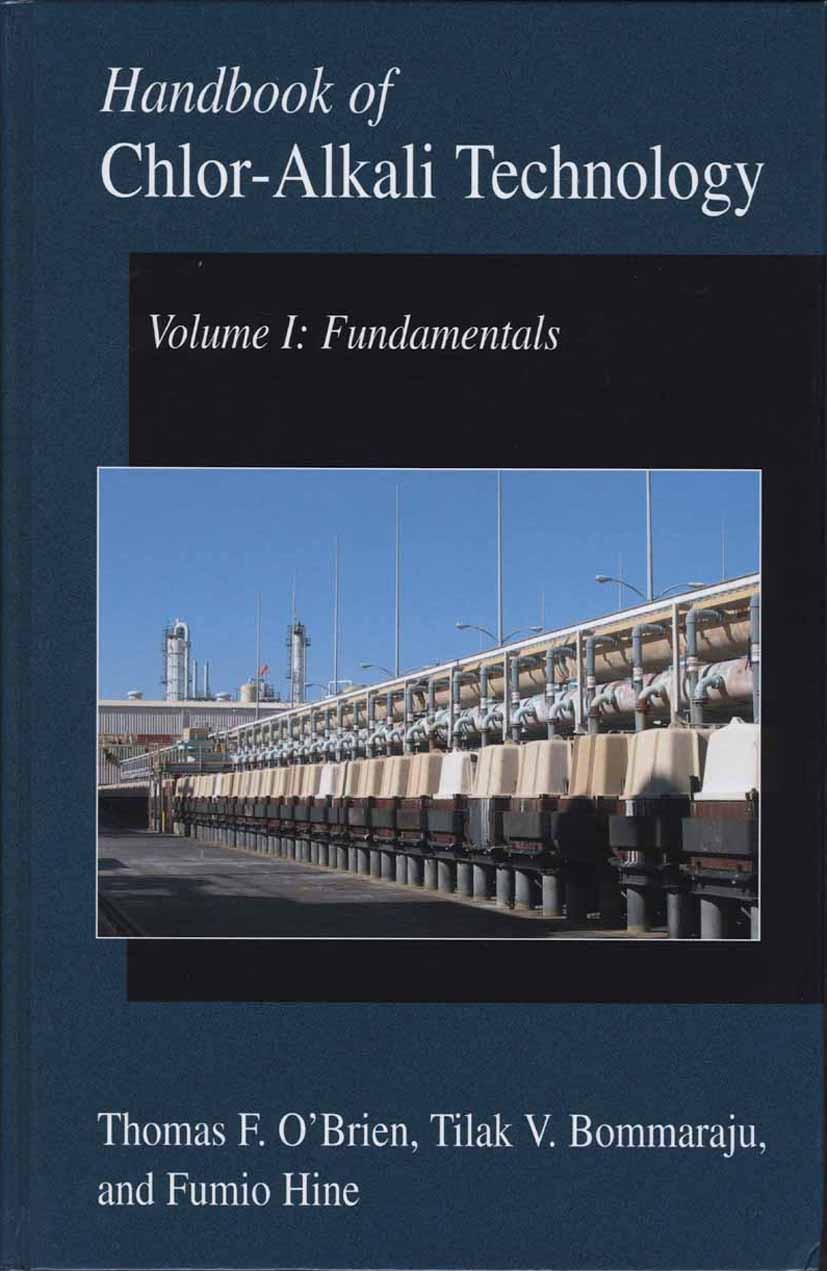

| 书目名称 | Handbook of Chlor-Alkali Technology | | 副标题 | Volume I: Fundamenta | | 编辑 | Thomas F. O’Brien,Tilak V. Bommaraju,Fumio Hine | | 视频video | http://file.papertrans.cn/421/420989/420989.mp4 | | 概述 | Concentrated treatment of all aspects of technology and handling directly related to the products of electrolysis.Thoroughly up to date and should become the standard reference in its field.Includes s | | 图书封面 |  | | 描述 | Foreword:- It is surprising that we had to wait so long for anew book that gives a comprehensive treatment of chlor-alkalimanufacturing technology. Technologists are largely still making dowith the classical book edited by Sconce, but that is more than thirtyyears old. At the time of its publication, metal anodes were justbeginning to appear, and ion-exchange membrane technology was confinedto laboratories. The various encyclopedias of industrial technologyhave more up-to-date information, but they are necessarily limited intheir scope. Schmittinger recently provided an excellent shortertreatment of the broad field of chlorine technology and applications.After discussing electrolysis and the principal types of cell, this,too, gives rather brief coverage to brine and product processing. Itthen follows on with descriptions of the major derivatives and directuses of chlorine and a discussion of environmental issues. .The last feature named above has relieved the authors of this work ofthe obligation to cover applications in any detail. Instead, theyprovide a concentrated treatment of all aspects of technology andhandling directly related to the products of electrolysis. It coversthe f | | 出版日期 | Book 2005 | | 关键词 | Brine treatment; Cell operation in electrolysis; Caustic soda; Ion-exchange membrane; Brine preparation | | 版次 | 1 | | doi | https://doi.org/10.1007/b113786 | | isbn_ebook | 978-0-306-48624-1 | | copyright | Springer-Verlag US 2005 |

The information of publication is updating

|

|

|Archiver|手机版|小黑屋|

派博传思国际

( 京公网安备110108008328)

GMT+8, 2026-1-3 10:48

|Archiver|手机版|小黑屋|

派博传思国际

( 京公网安备110108008328)

GMT+8, 2026-1-3 10:48